Table of Contents

Report

Do not forget to adopt and follow stricly the International System of Units conventions in your report.

Acknowledgment

First of all we would like to thank ISEP and Nídía Sá Caetano for giving us an opportunity to perform this project and again extra thanks to Nídía for all her help and patience. We would also like to express our gratitude towards all the supervisors: Maria Benedita Malheiro, Manuel Santos Silva, António Ferreira da Silva, Maria Cristina Ribeiro, Paulo Ferreira and Pedro Barbosa Guedes who were a great help while dealing with all problems occuring during the semester. We would also like to give special thanks to Joao Fransisco Silva who helped us with the parts assembling. Thank you also Ana Barata for leading us with writing all of the deliverables.

Abstract

Nowadays, excessive fuel consumption has become a serious problem. People are searching for new solutions of power production. Fortunately, there are several options on how to obtain sources of energy without devastating already destroyed environment. One of these solutions is growing microalgae, from which biodiesel can be obtained. This report presents steps to create the device to harvest the algae by drying them with the usage of solar energy. Such alternative to already existing methods is competitive as far as energy usage is concerned. Working on microalgae lets us feel that we may contribute to the broad field of biodiesel derivation investigation. The solar algae dryer is a distiller that gets rid of the unnecessary water from the algae solution. This report describes what kind of technologies, materials and equipment were used in order to build the solar algae dryer prototype. It also presents the device from ethical and sustainable point of view. The marketing plan for product commercialization and possible future enhancements are also described.

Glossary

Microalgae: a vast group of photosynthetic, heterotrophic organisms which have an extraordinary potential for cultivation as energy crops

Biodiesel: a vegetable oil- or animal fat-based diesel fuel consisting of long-chain alkyl (methyl, propyl or ethyl) esters.

Bioremediation: the use of micro organismal metabolism to remove pollutants.

Nutrient: a chemical that an organism needs to live and grow or a substance used in an organism's metabolism which must be taken in from its environment.

UV radiation: light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm, and energies from 3eV to 124 eV.

Deontology: branch dealing with duty, moral obligation, and right action.

Decree: a formal and authoritative order, especially one having the force of law.

Community: a social group of any size whose members reside in a specific locality, share government, and often have a common cultural and historical heritage.

Liable: legally responsible.

Sensor: is a converter that measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument.

Capacitor: is a passive two-terminal electrical component used to store energy in an electric field.

Community: a social group of any size whose members reside in a specific locality, share government, and often have a common cultural and historical heritage.

Deontology: branch dealing with duty, moral obligation, and right action.

Decree: a formal and authoritative order, especially one having the force of law.

EPS: European Project Semester

ISEP: Insituto Superior de Engenharia do Porto

LED: Light-Emitting Diode

Liable: legally responsible.

Microalgae: a vast group of photosynthetic, heterotrophic organisms, which have an extraordinary potential for cultivation as energy crops

Nutrient: a chemical that an organism needs to live and grow or a substance used in an organism's metabolism, which must be taken in from its environment.

Sensor: is a converter that measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument.

SWOT: Strength Weakness Opportunity Threat

USP: Unique Selling Point

UV radiation: electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm.

1. Introduction

1.1. Team

We are an intercultural team of students which is doing the European project semester on the Instituto de Engenharia do Porto, our team consists of:

Table 1. Team members

1.2. Problem

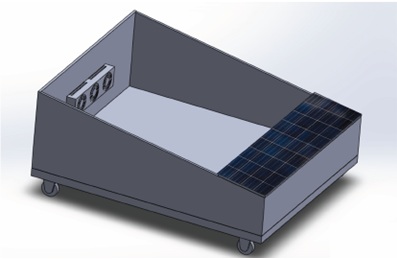

The problem we were presented was how to dry microalgae solution using solar energy. Even though there are plenty of methods of algae drying, only some of them introduce sun radiation into the process. Hence, our idea was to create a distiller that would incorporate direct and indirect solar radiation, making use of a solar panel. We thought of prototyping solar algae dryer that would be competitive to already existing devices.

1.3. Motivation

From the start we were drawn to the projects that dealt with solar power and had eco-friendly feature. What attracted us the most to the solar dryer was the fact that it is a project that might help in the bio diesel development. At present high use of fossil fuels is one of our biggest contemporary problems. The solar dryer is going to be developed for the Chemical Engineering Department at our school. For us that was another advantage. So we chose this project because we want to be a part in the search for a more ecologically friendly alternative than fossil fuel is. The fuel that has been used so far is limited and it is polluting the earth.

1.4. Objectives

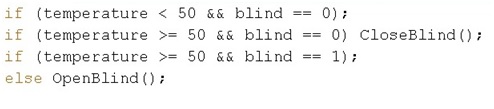

The main objective of the work is to create a device to dry microalgae that uses solar power to be operated. It must have a safety system that hinders it from working if the temperature exceeds 50°C. The reason for that is the fact that algal biomass, for instance oil or pigments, so what we would like to get after drying, may easily get spoiled in elevated temperatures. This problem is elaborated in details in further part of this report. Other aspect is that the whole process has to be finished in one day. Our idea is to develop a dryer that uses small amount of power.

1.5. Expected Results

We expect that the Solar Dryer will fulfill the clients needs which are drying algae with the use of solar power. We expect it to dry the algae to less then 10 % humidity in 24 hours. We also expect our algae-dryer to be one of the most energy efficient in the market.

1.6. Product planning

Regarding the work plan we divided our task into three modules. The general milestones together with a start and end date for every task are located in the Gantt chart shown in Figure 2. Furthermore, we allocated each task to the team members, which is represented in the task allocation shown in Table 2. Finally, every task is specified and defined in weekly sprints as you can see in figure 1. This planning can be better observed in the Gantt chart below in Figure 2.

Figure 1. Sprint

Figure 2. Gantt chart

Table 2. Task allocation

1.7. Structure of the Report

This report is structured in seven different chapters.

The first chapter is the Introduction and presents the problems we are facing, the motivation, the objectives and the results we expect to achieve.

In the second chapter, the State of the art, we describe the different technologies already available in this fields, and present the ones that we have chosen to use in our project.

The marketing plan, included in chapter three, presents the Market analysis, positioning and segmentation as well as a Market mix.

In the fourth chapter we present the Eco efficiency Measures for Sustainability, highlighting the importance of sustainability in the engineering area and including a life-cycle, and energy consumption analysis.

The fifth chapter describes the Ethical and Deontological concerns of our project, it is divided into two subcategories: Legitimacy and Legality.

The sixth chapter of the report concerns the Project development where the proposed solution of our project is explained.

Lastly, in the conclusion chapter, the discussion about our project is included as well as reference to possible further developments.

2. State of the Art

In this chapter we will state what we are using for our solar algae dryer. Figure 3. gives a clear overview: how the solar algae dryer works.

Figure 3. Overview

2.1. Requirements

From the very beginning our main concern was low power consumption. Studying the solutions present on the market and the one our client is utilizing - centrifuge, we noticed that in order to be competitive, we need to diminish the power consumption. Yet, there was some criteria we needed to follow – one of which was solar energy usage. We thought of many solutions including for example hydro cyclone or algae harvester working on assembly line, but as our aim was to minimize power consumption, we focused ourselves on distilling process.

We were supposed to work with solar power, taking advantage of that. Consequently, we decided to use direct solar radiation in distilling process to evaporate water. Also, the power coming from solar panel runs all the electrical appliances used in our product. Those are: microcontroller, diodes, temperature and level controllers and fan.

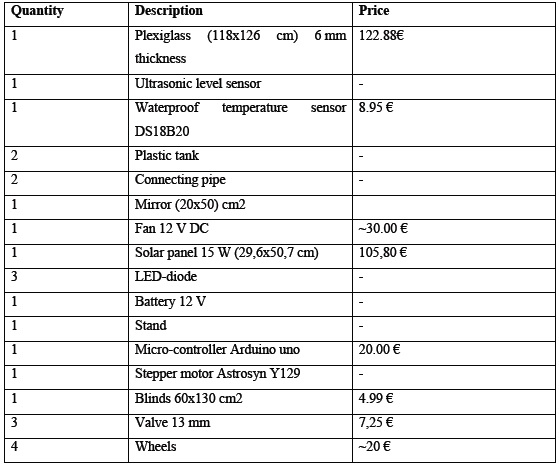

Not only the solar energy usage and low power consumption was our requirement, but also the budget of the project. Because of that, we tried to find all the needed parts at ISEP. While choosing the equipment necessary to build solar algae dryer, low, affordable cost, especially at local supplier’s stores, was one of our major criterion.

It is also good to mention that our project is supposed to be replicated, hence our target is to create well working prototype suitable for tests concerning future enhancements.

Furthermore, the product must have had several functionalities. One of the major concerns was overheating of the solution. Algae may get damaged by excessive temperatures, so it was indispensable to secure the device with the temperature control system. We also wanted our system to inform us about the end of the whole process. All of the systems also needed to be controlled.

Furthermore, the product must have had several functionalities. One of the major concerns was overheating of the solution. Algae may get damaged by excessive temperatures, so it was indispensable to secure the device with the temperature control system. We also wanted our system to inform us about the end of the whole process. All of the systems also needed to be controlled.

2.2. Related Projects and Products

To find a proper process to dry the algae in a way that our products needs are fulfilled there must have been a research done on this topic. That is why we provided a search on methods and products that already exist and are used for algae cultivation. It is worth saying, that most of it are photo bioreactors, used for mass evaluation of algae species and their production. At this point it is worth to present how the photo bioreactor works. It is a closed system, that does not exchange gases and contaminants with the environment. It is referred as a bioreactor with a light-supplying system to introduce the photonic energy to the microalgae, in this case, to help it grow faster. Most of the times it is a system of pipes, with the solution of algae and water inside. There are few types of photo bioreactors, varying in position of the pipes. There are ones, that are built close to the ground, installed in parallel to the ground, just like the product in figure 3 from “Solix” which is a company from the United States [1].

Also another company from The Netherlands called Algaelink NV has a similar product. Its idea is also to dry algae with solar power. But the design is a thing that differs, it looks more like two ours combined together. The inclination starts from the top, in the middle and goes down both sides.

Another difference is of course the size. Its length is 18 m and drying area of 20 square meters, therefore much bigger. It is supposed to be used for mass-production. The water also evaporates only with the sun energy. But despite the fact that this product is very similar to ours, it has one important difference: it does not dry algae on a small laboratory purposes and is not controllable through electronic or mechanical devises.

Figure 4. Algae farm

This algae farm is built as a system of thin pipes to make sure that maximum amount of light comes to every single part of the solution to fasten the process. The advantage of this product is definitely high speed of growing of the algae and in a mass manner. However the disadvantage is that it is expensive to build. Therefore, as we need a device that dries just 5 litres of the solution, and that at the same time has to be cheap, this system does not fit our needs. As the algae farms using photo bioreactors are the most common way of harvesting the algae and of extracting the oil from them, it is worth saying a bit more about different types of the mentioned devices. Nowadays, one of the most developing types is so called “Christmas tree” photo bioreactor, designed by the German company “Gicon” in Dresden [2]. It is named that way, because it is wider at the bottom and gets narrower at the top, just as represented in the Figure 4 below:

Figure 5. Reactor [2]

This reactor is built in such manner to measure that the sunbeams get to every part of the structure as long as possible. Other advantage of this system is that it saves space in comparison to previously mentioned photo bioreactor of a traditional structure. Because of the pipes two-walled technology, it is possible to change the surrounding temperature extremely quickly, which also helps to harvest the algae rapidly. As the producer highlights, the design is extremely lightweight, therefore, easy to build and manage, and as they state, power-efficient, comparing to other existing technologies.

2.3. Tank

The main part of our project is the tank where the algae will be dried. Every part of the project has to fit with the tank, and therefore we need to have the tank as a base for our project. The whole system was supposed not to exceed 1 m2, so we wanted the bottom of the tank to cover the most area possible. When deciding which material to use for the tank, we must start from the needs of the tank.

- It has to be completely waterproof

- At least the top of it has to be transparent

- It has to be easy to assemble

- Light material

- Environmental friendly material

- The price has to fit in our budget

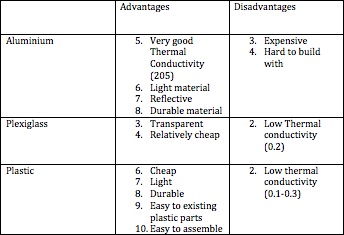

With these needs we started to consider different materials to build the tank. In Table 3 we have listed the advantages and disadvantages for three different material solutions for the tank.

Table 3. Different materials for the tank

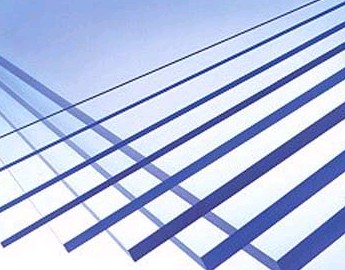

After analysing this, we thought that it would be a good idea to build the tank out of aluminium, because of its good thermal conductivity. But after considering the alternatives a little bit more we stated that the plexi glass will probably be the best solution. We would anyway need the plexi glass for the top of the tank, and therefore it would be the best way to build the whole tank out of plexi glass. In this way we can assemble it more easily and we also get transparent sides for the tank. Plexi glass is also cheaper than aluminium and it’s not too heavy. We can also easily make the bottom of the tank absorb the sun more efficiently by painting it black or reflect the sun by adding mirrors.

2.4. UV & Plexiglas

One of the very important aspects as far as algae drying is concerned, is to make sure they will not get damaged during drying. It is known that algae suffers from excessive UV radiation. As our device serves for drying algae with the help of sun beams, they will be constantly exposed to UV radiation. Hence, in order to prevent damage, it is wise to install some kind of filter protecting them from harmful UV radiation. Before coming to solution, let us firstly focus a little on UV radiation itself.

According to Gary Zeman member of the Health Physics Society, ultraviolet radiation is this part of the light invisible to our eyes, a portion of electromagnetic spectrum in between 400 – 100 nm. In addition, it also has its main components, which are UVA (320-400 nm), UVB (290-320) and UVC (220-290 nm) radiation. The most common one is the UVA radiation needed by humans for the synthesis of vitamin D, UVB radiation, on the other hand, is considered the most harmful. That is due to the fact that this kind of UV radiation has enough energy to cause “photochemical damage to cellular DNA“ [3].

Obviously, such problem cannot be ignored especially if our aim is to get advantage from algae structure. Destructive properties of UVB are also proven by the fact that it impairs photosynthesis in many plant species, so also including microalgae [4].

We have considered two possible solutions. The first one is very simple - glass. Glass blocks over 90% of the light below 300 nm [5], so the hurtful UVB radiation will not affect the process. In order to get 100% protection, we thought of using laminated glass. It consists of two pieces of ordinary glass connected by PVB - Poly Vinyl Butyral. Such structure ensures 99% of UV radiation blockage, but it is also very hard, which gives us the other advantage in our design properties [6]. The other advantage is that glass is completely transparent, and taking into account fact that our distiller needs light to warm up the solution to get it evaporated, this feature is really important. Transparency means that it does let through the visible light and Infra red (IR), which causes heat. The device is aimed to be used outside, thus glass transparency seems extremely proper.

The other solution is plexi glass, so Poly(methyl methacrylate). It has almost the same properties as simple glass does, but has a main advantage over glass. Meaning, it is significantly lighter. This feature comes in really handy, taking into account the fact that we are considering the dryer prototype to be replicable. One cannot imagine a huge container made of glass that can be easily reassembled or to be lifted up. According to the producer, plexi glass has following properties: it has low density, so it lets the sun beams through easily, its resistance towards abrasion is close to the one of aluminium, it is resistant to any chemicals, it is completely transparent (this feature was already mentioned to be of great importance) and the most important is that it is a protection from UV radiation [5].

2.5. Temperature controller

One of the requirements of our solar dryer was to have a temperature controller installed. This is necessary to protect the algae, because the algae will get damaged if the temperature rises over 50° C. The requirements of this temperature controller are:

- measure the temperature inside the tank

- produce the sound when temperature rises to 50°C → Adjust the temperature

- be waterproof

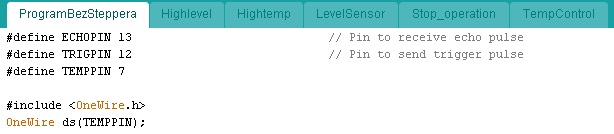

For this purpose we were thinking of using a temperature sensor that will measure the temperature inside the tank and if/when the temperature rises to 50° C it will give a signal to the micro-controller and the cooling down process will start. The chosen temperature sensor is a waterproof temperature sensor model DS18B20. This temperature sensor is connected to our Arduino micro-controller and sets an alarm when the temperature rises above 50°C. The block diagram of Figure 5 shows the major components of the DS18B20. The DS18B20 has four main data components: - 64-bit lasered ROM, - temperature sensor, - non-volatile temperature alarm triggers TH and TL, and - a configuration register. [7].

Figure 6. Block diagram for temperature sensor [7]

Features of temperature sensor DS18B20:

- Requires only one port pin for communication

- Requires no external components

- Multi drop capability simplifies distributed temperature sensing applications

- Power supply range is 3.0 V to 5.5 V

- Zero standby power required

- Measures temperatures from -55°C to +125°C

- +/- 0.5°C accuracy from -10°C to +85°C

- Thermometer resolution is programmable from 9 to 12 bits

- Converts 12-bit temperature to digital word in 720 ms (max.)

- User-definable, non-volatile temperature alarm settings

- Alarm search command identifies and addresses devices whose temperature is outside of programmed limits [7].

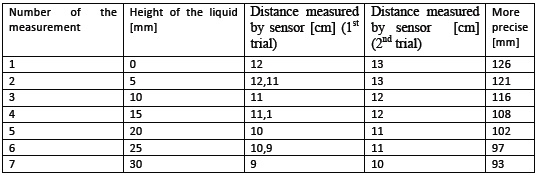

2.6. Water level controller

In order to be able to control when the drying process is ready, it is necessary to have some kind of sensor that tells us when it is ready. The best way of doing this is to put a sensor attached to the water level that alarms when we have reached our goal of 10% water left in the solution. The requirements for this sensor are:

- be precise (water level will drop from ~20 mm to ~2 mm)

- be able to work in temperatures between 0°C - (+)60°C

- give a signal to the micro-controller when the water level is low enough (drying process ready)

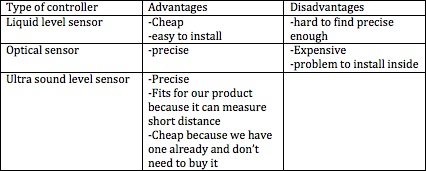

When facing this problem we thought about different solutions to solve it, they are listed below in table 4, considering their advantages and disadvantages.

Table 4. Water level sensors

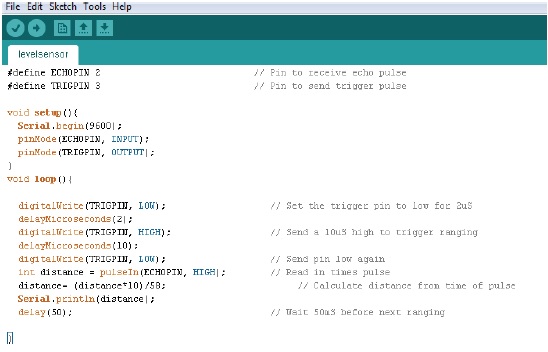

The easiest and cheapest way to control the water level is the liquid level sensor. It works with a moveable float, and floats with the water level, and it can be adjusted to the water level you want it to alarm. The problem is that it’s hard to find one able to measure the levels that we are going to have in our tank. Because of this problem we will choose the Ultra sound sensor. There is already one at school that can be used, and it will be adaptable to our solution. This sensor will be connected to the Arduino micro-controller, and alarm when the water level is low enough and the process is ready. Ultrasonic level sensors are used for non-contact level sensing of highly viscous liquids as well as bulk solids. They are also widely used in water treatment applications for pump control and open channel flow measurement. The sensors emit high frequency acoustic waves that are reflected back to and detected by the emitting transducer. The chosen sensor is a Devantech SRF04 Ultrasonic Range Finder.

Below features of the ultra sound sensor are presented and also a picture of the SRF04 in Figure 6.

Features:

- Voltage – 5 V

- Current – 30 mA

- Frequency – 40 kHz

- Max range – 3 m

- Min range – 3 cm

- Sensitivity – Detect 3 cm diameter broom handle at > 2 m

- Input Trigger – 10 uS min. TTL level pulse

- Echo pulse – Positive TTL level signal, width proportional to range.

- Small size – 43 mm x 20 mm x 17 mm height [8].

Figure 7. SRF04 Ultrasonic Range Finder [8]

2.7. Fan

The speed of the distilling process depends on the speed of evaporation. Evaporation speed depends on the temperature of the air and the algae, size of the exposed surface to the air, concentration of the substance evaporating, pressure and the flow rate of air. We can control this last factor. We want to make the air circulate by adding a fan. We considered a fan with a heater build in. But we decided that the gain of hot air is not worth the loss, it uses a lot more energy.

Then we had an option to make the system closed or open. If the system would be open, there would be a supply of colder fresh air. But since we don’t need the supply and the inside air just needs to move faster we decided to make the system closed. Another advantage of a closed system is the fact that it is more weather proof, for instance no rain can enter the tank. Our choice was to use Humid protect 12 V DC fan. The model that we decided to buy has following specifications:

Table 5. Fan specifications [9].

Taking into account the power consumption and the expected power output of solar panel, we believe it can properly work for the time of evaporation.

2.8. Microcontroller

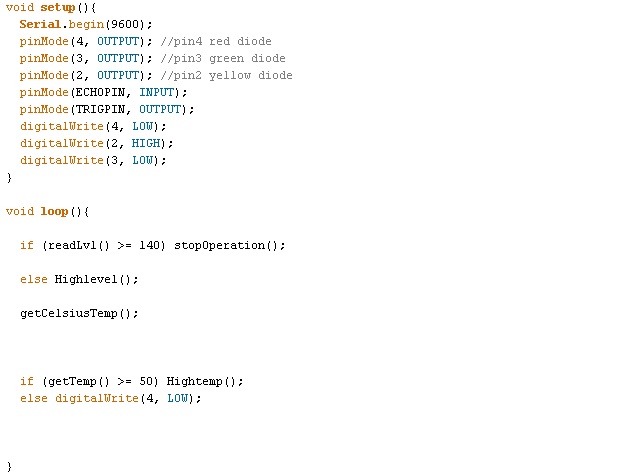

To make sure, that the whole system works just the way we want it to, we have to install a microcontroller, which has to be programmed to distribute tasks to the previously mentioned parts, such as temperature controller, level controller, the diodes, fans and a mechanical system responsible for reducing the temperature inside the tank, not to be higher than 50°C. The board we chose is Arduino Uno board with microcontroller ATmega328.

We use it, because of its simplicity, but at the same time enough number of analog and digital ports. Because of the fact that we require just one analog and few digital ports such board is enough. Here in Table 1. are shown the official specifications taken from the producer's webpage.

Table 6. Arduino specifications [10]

| Microcontroller | ATmega328 |

| Operating Voltage | 5 V |

| Input Voltage (recommended) | 7-12 V |

| Input Voltage (limits) | 6-20 V |

| Digital I/O Pins | 14 (of which 6 provide PWM output) |

| Analog Input Pins | 6 |

| DC Current per I/O Pin | 40 mA |

| DC Current for 3.3V Pin | 50 mA |

| Flash Memory | 32 kB (ATmega328) of which 0.5 kB used by bootloader |

| SRAM | 2 kB (ATmega328) |

| EEPROM | 1 kB (ATmega328) |

| Clock Speed | 16 MHz |

Below in Figure 8. the Arduino Uno board is shown:

Figure 8. Arduino Uno [10]

2.9. Solar Panel

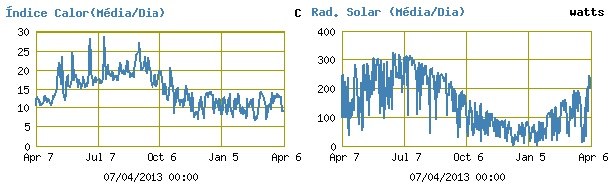

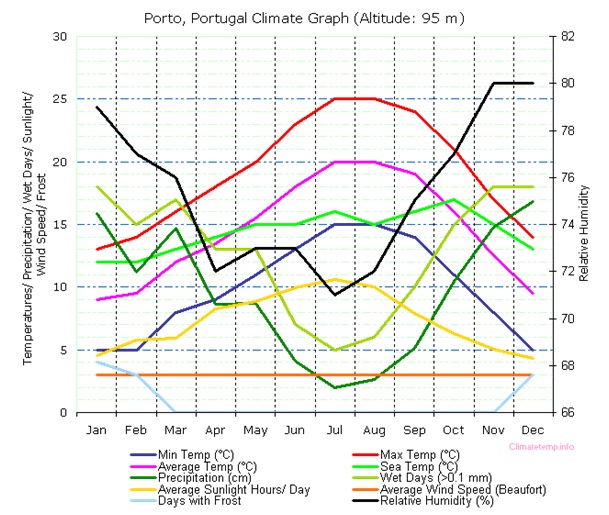

The main idea of this project was to power up the system just from the solar panel. It had to be checked what output power would satisfy our needs and it has been decided that 15 W solar panel would be required. Below are shown initial calculations to make sure that the power output from the panel is enough to support all components of the system. Concerning the peak power of the solar panel it will reach the value of 360 Wh a day at its maximum. Using the PVGIS site we may calculate the average power taken from the sun in different areas of the world [11]. Another aspect, that is needed, is the factor that describes ratio of power output per hour and peak power of the solar panel at concrete place on Earth. In our case it is North of Portugal and the value is equal to 1400 kWh/kWp. Per one day, one fan consumes:

2.5 W × 24 h = 60 Wh

Arduino needs 12 Wh and the diodes need around 10 Wh. Summing up maximum power consumption a day equals 82 Wh. So in a year we would need:

0.082 kWh × 365 days = 29.93 kWh per one year

Taking into account the factor discussed previously, in this region peak power needed to support our system is equal to:

29.93 [kWh] / 1400 [kWh/kWp] = 21.4 Wp [watts peak]

As can be easily seen this value exceeds the peak power of our chosen solar panel, but it is worth to point out, that these calculations refer to weather conditions throughout the whole year, also on the cloudy days. At that time our product would not be effective and probably also not used. Due to the fact that our goal is to provide a product that is, at the same time, not bigger than one square meter, power saving and cheap, we would not like to use a bigger panel. It would of course develop the operation of the device, but would highly rise the costs.

For the ultrasound sensor and temperature sensor there are no official data in the datasheets, concerning power consumption of these devices, but it is stated that they are can be supported with the power from the data line, so we may assume that the amount of output power of our solar panel more than enough for these two controllers. Other components that gain power from the supply are two diodes, but as in previous case the amount of power needed for their operation is not very significant. The power of a diode is easy to be calculated from the formula:

P= V×I, where

V - voltage on the diode I - current flowing through the diode

Knowing, that the voltage on the diode generally does not exceed 3 V and the current values of standard led diodes do not exceed 75 mA the maximum power on the diode is 0.225 W, so 0.5 W is enough to support both of them.

Other components of the system that have to be powered by the energy taken from the sun, as previously mentioned, are the temperature controller, level controller, diodes indicating if the wanted level of the liquid has been reached or if the temperature exceeds 50°C. Other part of our design that has to be supported by the power from the solar panel is the step motor, working with blinds on the top of the tank to control the temperature inside the dryer, by reducing the sunbeams acting on the algae solution. Of course the whole system could not work with the energy taken directly from the panel. It happens due to the fact, that the sun does not operate on the same level of intensity all the time and the idea for the system is to work all the time. That is why the battery was needed to be applied to be charged by the panel. We have chosen a 12V/ 2.3 Ah battery, because the whole circuit is supposed to operate in this voltage. Therefore, an additional circuit between the panel and the battery will be needed to make sure that the battery lasts for longer time.

The panel that we chose is shown in Figure 9 below:

Figure 9. Solar panel [9]

Table 7. Solar panel specifications [12]

| Power Rating | 15 W |

| Power Voltage Max | 17 V |

| Current at P Max | 890 mA |

| Open Circuit Voltage | 21.5 V |

| Short Circuit Current | 970 mA |

| Length | 507 mm |

| Width | 296 mm |

| Height | 25 mm |

| Weight min. | 2.56 kg |

2.10. Battery

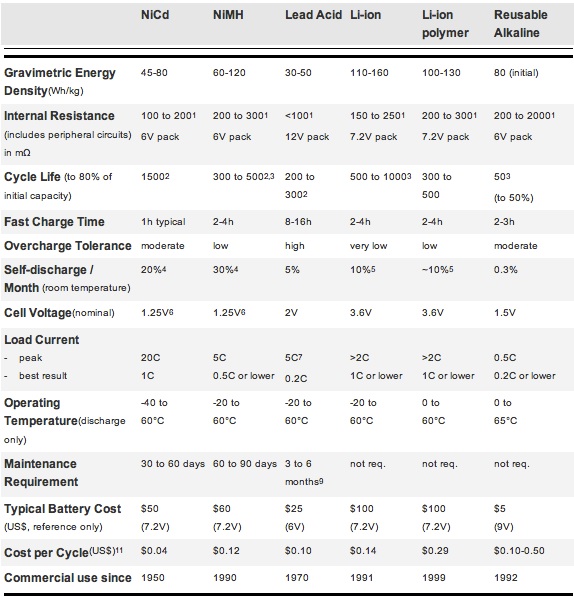

In order to supply our device with electricity all the time we need a battery. There are many different types of batteries and here are presented the most common ones.

Nickel Cadmium (NiCd) — mature and well understood but relatively low in energy density. The NiCd is used where long life, high discharge rate and economical price are important. Main applications are two-way radios, biomedical equipment, professional video cameras and power tools. The NiCd contains toxic metals and is environmentally unfriendly.

Nickel-Metal Hydride (NiMH) — has a higher energy density compared to the NiCd at the expense of reduced cycle life. NiMH contains no toxic metals. Applications include mobile phones and laptop computers.

Lead Acid — most economical for larger power applications where weight is of little concern. The lead acid battery is the preferred choice for hospital equipment, wheelchairs, emergency lighting and UPS systems.

Lithium Ion (Li‑ion) — fastest growing battery system. Li‑ion is used where high-energy density and lightweight is of prime importance. The technology is fragile and a protection circuit is required to assure safety. Applications include notebook computers and cellular phones.

Lithium Ion Polymer (Li‑ion polymer) — offers the attributes of the Li-ion in ultra-slim geometry and simplified packaging. Main applications are mobile phones. Table 8 compares the characteristics of the six most commonly used rechargeable battery systems in terms of energy density, cycle life, exercise requirements and cost [13].

Table 8. Different battery types [13]

At first we thought about placing 12 V battery, but because of the lack of the fan in our system we chose a 9 V battery. We did it due to the fact that every other part works on 5 V. The battery we chose is shown on the Figure 9 below.

Figure 10. 9 V type battery used

2.11. Stepper motor

In order to control the temperature inside the tank we need to be able to cover the top of the tank, for this we are using blinds and for controlling the blinds we need a motor. The stepper motor will be controlled by the Arduino and regulate the blinds according to the temperature inside. The requirements of the steperp motor is to be powerful enough to control the blinds but at the same time not use a lot of power. The step motor we have chosen is a 12 V Astrosyn Y129 stepper motor shown in figure 10.

Figure 11. Stepper motor

2.12. Conclusions

Summing up, all the products that we have chosen after a brief research were picked because of their contribution to our product, being low energy consuming, cheap and that it would fulfill our needs. We chose such solar panel due to the fact that it just has to be powerful enough to supply power to other components and cannot be too heavy. The fan have to give enough velocity of air to rise the speed of the process.

After a huge study of temperature and liquid level controllers we decided to use ultrasonic level controller. The reason was that most of other products did not have such small range of operation, as we needed. The temperature controller however was chosen because of the fact that it sends analog signal, what facilitates circuit design. The last component to select was the microcontroller, which had to be simple, because of the fact that our circuit is not a complicated one. The only thing that had to be checked was the number of digital and analog ports in the board. That is why Arduino Uno was chosen.

3. Marketing

3.1. Introduction

Executive summary

In times of worldwide air pollution and decreasing energy resources it is absolutely necessary to support systems that do not harm product environment and use less energy. Our product will fit into the actual eco-political and economical trends of “green energy”. To concentrate on the right competitive advantages of our product, it is very important to study potential competitors and of course the customer needs. Therefore we will concentrate on the European market for analyzing the advantages and disadvantages of nowadays' solutions.

Product description

Product: Solar dryer

Definition:

- What?

Our project is to develop a microalgae dryer, powered only by solar energy. We dry the algae by evaporating the water.

* Wherefore?

At the moment one of the biggest challenges is the enormous consumption of fossil fuel. In contrast to ordinary systems the oil contained in micro algae can be used as an ecological and sustainable solution because it is usable as alternative fuel.

- Why?

We want to be part of the development of a more ecologically friendly solution for fuel. We believe that we have developed a solution which is in line with the current eco-political and economical trend of “green energy”. Today’s fuel is limited and polluting the Earth.

- How?

The Solar dryer is going is a solution that is very energy-efficient and uses renewable energy. As a by-product the algae absorb CO2 to produce biomass.

3.2. Market Analysis

A comprehensive market analysis examines the attractiveness of a special market within a specific industry. This can help to determine the target market and the need for the product. In order to be successful with the launch of a product, in particular the “Solar Dryer”, a scan of the internal and external environment is an important part of the strategic planning. In order to identify and document strengths, weaknesses, opportunities and threats we will use the SWOT Analysis. The external environment includes all factors with impact from the outside. They are influencing the ability to develop successful relationships with the target customers. With regard to the specific company, these factors can be divided into micro environmental and macro environmental.

3.2.1. Macro environment

In general, the macro environment is composed of those factors on which the company has very little impact on and they often require changes in several marketing aspects. The important factors compromising the macro environment of marketing are demographic, economic, socio-cultural, natural, technological and political-legal. We describe the influence of each factor in more detail in the next sections. Regarding our project, the macro environment is concerned demographic, technological and political aspects. These are characterized in the next sections.

3.2.1.1. Demographic

Demography is the study of human population, which includes different types: density, location, age, occupation and other terms. The major interests of marketers are people, because demography involves people and people create markets. The only constant thing in life is changing, the same applies for demographic trends.

Figure 12. Demographic chart

The demographics development shows that the population has increased.

Figure 12 above shows that the worldwide population will increase to about 8 billion people in 2030. Worldwide, there are around 900 million cars in 2007, of which 231 million in the EU [14]. This number increases to 1.069.097.774 cars in 2011 [15]. Consequently, we have about 200.000.000 new registered cars from 2007 to 2011. One reason for this is, that mobility and flexibility are becoming important topics to be successful and competitive in times of growing globalization.

Table 9. Cars per inhabitants (APA/Red.)

A serious resulting problem caused by the increasing population is high air pollution. Nevertheless, the energy reserves decrease rapidly and as a consequence the need of alternative fuel increases. This shows all the more that our system should run with renewable and sustainable energy.

3.2.1.2. Political

Political factors influence organizations in many ways and are able to create strengths and opportunities for organizations.

Finally, since the failure of the UN Climate Change Conference in Copenhagen 2009, everyone should be aware of its results. It was one of the biggest conferences in history, but unfortunately the one with the most unsatisfactory results [16]. A solution to be followed after the Kyoto-Protokoll was not found as well as none affirmative covenant concerning the bisection of carbon dioxide emissions was made. Anyway, most of the European states already implemented some concepts in order to work on these challenges.

For instance, the German government supports research programs in the “green energy” area [17]. The university of Senftenberg and the “Green Mission” GmbH got 4 million Euros for the algae research in 2010. Concerning research, the three main categories are taken into consideration: Which strain of microalgae is the best? What is the energy balance of the algae cultivation? At what amount of CO2 supply do algae grow most effectively?

Meaning, rather they are not interested in drying the algae as fast as possible. The aim of this project is to get satisfactory results to answer the three main categories. Consequently, these should be our target projects, because we find a current win-win situation. This implies that we are able to integrate our solution in the existing system enabling them to get the necessary power by solar energy instead of fossil energy sources, and we will get the needed information to modify our system.

Other opportunities to raise the financial resources are funds from the European union. For instance, the Eco-innovation initiative is a part of the EU’s Competitiveness and Innovation Framework Program (CIP) [18]. This program is also linked to the Eco-innovation Action Plan (EcoAP), Europe’s green technology roadmap and the policy background for Eco-innovation [19]. These initiatives enable new products, processes or services which will create a beneficial impact on the environment to get into the market. Basically, this fund will not finance the whole requirements of our product. Nevertheless, it is useful to improve our product. Finally, we believe that we could be able to produce at lower cost as well as decrease the cost of the market launch.

3.2.1.3. Technology

Technology means continuous change. Consequently, technological force is rising by the used level of development and influencing organizational degree. Currently, we are using the newest technology and the fact that the whole system runs on solar energy also meets future trends.

3.2.2. Microenvironment

The microenvironment consists of five components. The first component is the organization’s internal perspective and its effects on the different departments. It is known that its several departments management levels have a great impact on the decision making progress. Secondly, microenvironment deals with suppliers, the intermediaries and the new developers cooperating with the organization. The third component considers the potential market, the producer, consumer, reseller, government and international markets. The prospective customers belong to the fourth part. The fifth component of the microenvironment consists of the public, including all potential organizations, which have an actual interest in the organization’s accomplishment to achieve its objectives.

3.2.2.1. Internal perspective

Referring to the organization’s internal environment as described above our organization is a team of four students from different faculties. Analysing each other’s capabilities we appointed each person to act as a manager of a certain department. Due to the fact that each member has its own responsibility we are able to make decisions in terms of the product’s development and product launch.

3.2.2.2. Intermediaries

In this case Intermediaries are not relevant for our solution. The product we are going to develop is really specific and requires explanation. Therefore, it is really important to focus on “one to one” marketing. If we are thinking about the future, could be interesting working with intermediaries since the market is aware of our product.

3.2.2.3. Customers

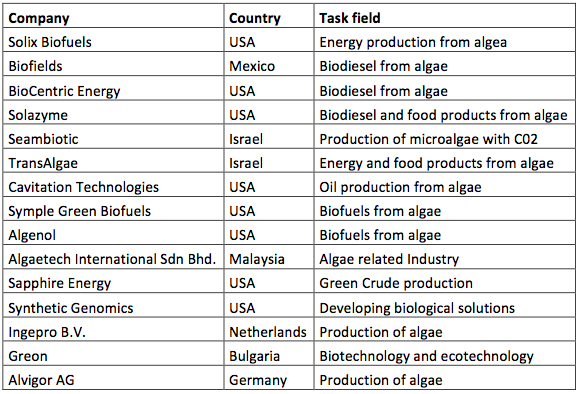

After analysing the market in terms of prospective customers, we identified companies in the energy already using the microalgae production to produce fuels. Accordingly, these companies are familiar with the idea and have already developed systems gaining biodiesel out of microalgae. We recognized that almost each company uses their own technology to dry the algae. In order to meet those needs, our product is developed on a standardized solution but it also offers features that can be customized to apply individual needs. Thereby the prospects have the opportunity to choose the most suitable solution. In Appendix we have included a list of international prospects.

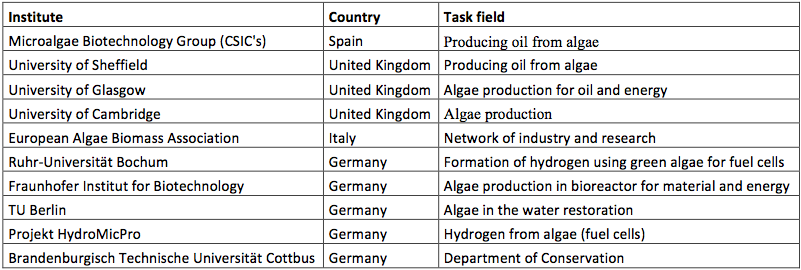

Table 10. Different algae related companies

The table shows that most of the potential customers are placed in the USA, but our current solution is not yet adjusted to their needs. Because these companies are focused on mass production and requiring a solution that fulfill their expectation of capacity, efficiency and establishment. In order to meet those needs we are going to improve our product making it the most suitable as possible for a sustainable relationship towards future prospects. Referring to the European market we also found some prospects, these are shown in Table 11 below. We are going to enter this market first, because with the use of given opportunities, which will be defined in the following, we are able to minimize existing market barriers. An other result of our market analysis is that universities and institutions belong to our potential customers, as they have been involved with the algae production, too. We believe that we can integrate our solution in existing systems enabling them to get the necessary power by solar energy instead of fossil energy sources.

Table 11. European prospects

Due the fact that our potential customers are organizations and institutions we distribute our product via Business-to-Business (B to B). Although our prospects are already operating in this very special market the “Solar Dryer” is still a specific product that requires explanation. As a result of this, we decided to focus on ”1:1 Marketing” activities. Referring to our organization this involves the person responsible for sales listening carefully to what the customer requires and then proposing how the product can be customized in order to replace the current power unit.

3.2.2.4. Competitors

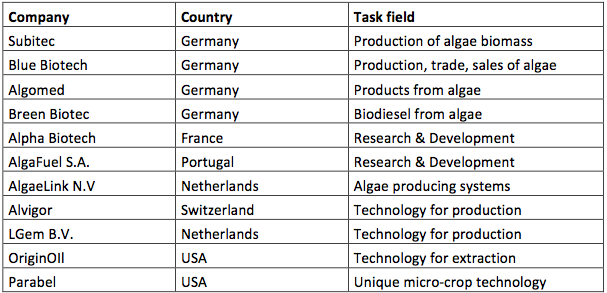

As long as an organization has no monopoly position it faces competitors affecting ones business’s profits by trying to take business away. Meaning, basically each prospective company can be a customer or a competitor. Referring to our target market the aim of the relevant companies is the mass production of algae. However, we identified a few companies listed below. These companies primarily specialized in producing and selling components to dry the algae.

Table 12. International competitors.

The general problem of nowadays’ solutions is the waste of energy. Furthermore, these systems have to decrease the high consumption of used materials and change to alternative energy instead of fossil fuel or electricity to run their system. Nevertheless, most of the existing solutions are faster then our system is going to be. Therefore, it is our aim to identify these strengths and weaknesses and using the obtained know how to create a sustainable and competitive solar dryer.

Currently, most of the existing parts are ideal for prototyping and adjust our client needs. But through permanent dialogs with prospects and carefully listening to their requirements we are able to specify our product towards future needs. As a result of this it is our objective to develop a strong competitive advantage by running the whole system on solar energy, decrease the energy consumption ,and finally create a solution which is easy to establish. Hence, our product delivers more added values for our customers than that of our competitors.

3.2.2.5. Suppliers

Furthermore, we intensify the networking with suppliers. We believe that cooperating with the energy sector is the first step to enter the market. Trough this network we can reach a large target market and our target costumers. For instance the networking with Achilles could be interesting. Communities for buyer or supplier already exist in the Achilles Group [21]. In addition to that we can use an existing system, and must overcome the need for complicated market immersion barriers. This allows us to quickly draw attention to our product without investing great marketing promotion.

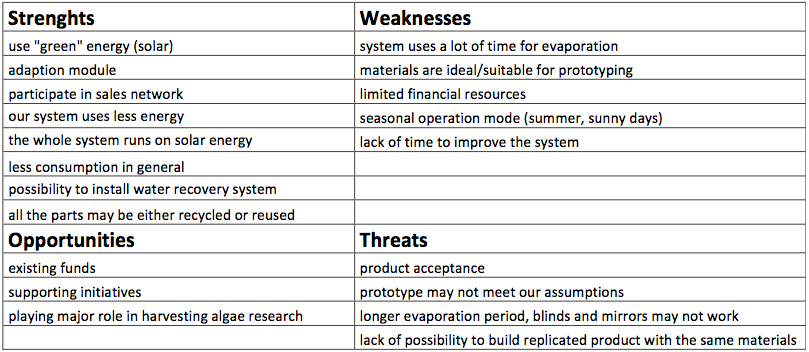

3.3. SWOT - analysis

To summarize the objectives concerning our product a SWOT analysis was made. The following table shows the clarified ideas (advantages & disadvantages of the environmental analysis).

Table 13. Swot analysis

3.4. Strategic objectives for our project (3-5 years)

In order to achieving an applied vision of our product and generate greater profit it is necessary to develop long-term, continuous strategies. Referring our product the following strategic objectives were defined.

1. Development of adaption module within 3 years

2. Customer satisfaction and long-term relationships

3. Spread our product to Europe within 5 years

4. Differentiation of module and service

3.5. Market segmentation

Market segmentation is the process of identifying prospective segments within the general market. Market distribution is really important because with the knowledge of our target market we are able to meet customer’s needs and create competitive advantages.

Summarizing the previous market analysis and objectives listed in the SWOT, is the result that the energy market is the most interesting market for our product. Because currently we have a lack of financial background and R&D resources, consequently choosing the market with the lowest barriers is one of our approaches. Referring to the market analysis the European market consists of the needed circumstances.

Even though, the main aspects of the analysis shows that most of current used materials are ideal for prototyping, but do not fulfill prospect’s needs because the product is adjusted to our client needs and these are not future needs. In the current situation it is challenging to enter the chosen energy market. Nevertheless, the bio diesel extraction out of algae is a new technology. Consequently, the research and development in this area is at its beginning. This implies that the demand of new eco-friendly solution exists.

Referring to our product it shows that we have to equip the solar dryer with specific functions. This enhancement leads us to change our first approach, which was to concentrate first of all on the European market first, into modifying it first of all.

To understand and meet customer needs, we need to know the main challenge of our target market. Today the major question many companies in the energy sector trying to answer is the following: How can we produce enough algae in order to meet the demand for alternative fuel such as for biodiesel? Concerning our product the market analysis shows that there are several well-established companies (e.g. Algae Link N.V. [22]) with a large financial background and specialized faculties enabling them to focus on mass production and distribution. Currently, the solar dryer cannot fulfill these given requirements so our product has to be further developed in order to replace conventional methods. However, our product is applied to meet the requirements in the future because most of the existing solutions are inflexible and have high energy consumption. Our value proposition is to develop a solar dryer which consists of the following features; large function variety, easy to establish, meet the customer’s sustainable approach, runs only on solar energy, and has less energy consumption. Only if we continuously enhance and adjust our product we believe that we are able to meet the long-term requirements of the energy market.

Therefore we split our target market into two groups. First we are selling our product to prospective universities to modify and improve our prototype. We are especially looking for independent laboratories researching to find the most efficient microalgae. The attractiveness referring this collaboration is based on collective conception of a sustainable future. Our solar dryer supports this behaviour and through this collaboration and the given results we are able to modify it successfully. After modifying our system and improving it towards future needs, our product will be able to enter the European Energy Market.

Available structures for implementation are placed in Europe. As already mentioned in the previous part, different opportunities such as existing funding’s supporting our product are given. Furthermore, political trade barriers are minimized, and the fact that all team members have gained their knowledge in different regions of Europe could be helpful to enter the market. In terms of launching our product in Europe we also take advantage of the fact that each team member comes from a different country in Europe.

Once our product is well established in Europe we believe that the American market offers further opportunities. This market also consists many competitors but with comparable inflexible solutions entering the market with an improved solar dryer will be possible. Referring this the remote future is to spread our product to Europe and gaining as much market share as possible. Afterwards, with the usage of advanced know how, gained experiences, and a solar dryer with outstanding features will enable us to access the American market.

3.6. Market positioning

The positioning task considers three steps: At first identifying possible competitive advantages, then choosing the right advantage, building up a basic position and selecting a collective strategy. It is very important to communicate the chosen position effectively to the market. The market segmentation and SWOT-analysis shows that the development of our product has to be orientated towards our customers’ approach because the circumstances in the existing market are different as well as duration and functionality. It appears that the existing solutions are inflexible and do not offer many features. To be successful once our potential target audience is convinced that our system does not only fulfill their requirements but also supports our customer’s own sustainability approach. Based on these results an effective positioning is realizable in the energy market. Certainly, improving and modifying our prototype is really important to develop a conclusive solution that is competitive.

The collaboration with universities is a vital step as this will give us the required know how, experiences in daily work, requirements of features and the demand of capacity. As a result of this, it is our objective to develop a strong competitive advantage by decreasing the energy consumption, run the whole system on solar energy and add several features for specific customer needs.

Referring our product and concerning our value proposition it has to be differentiated in several tasks. We believe that our product cannot be a “stand alone” solution. Once our system is installed our customers will not only be supported by our Customer Care Team but also be informed about the future development by our After Sales Service. This service plays an important role in terms of our product’s USP (unique selling point). Additionally, we will have an on-going development to gain as much market share as possible.

Summarizing our strategy. In total we will offer a main solution with an adaptation module that is easy to establish and adjusted to energy sector requirements listed above. In the first two to three years we pay attention on developing our competitive advantages through carefully listening to future requirements. In the following years we try to integrate our product in the European energy market by differentiating it in several tasks. In the distant future, since the market is already aware of our product and we are able producing it massively, we are going to participate in the American market. Through a mass productive solar dryer and the gained know how the American market requirements can be fulfilled.

3.7. Market Mix

3.7.1. Product

Our organization will offer a solar dryer that is a system consisting of a main solution with an adaption module. The adaption module is designed for specific customers’ needs such as capacity for bigger tanks. With this product customers can choose the most suitable solution regarding their specific demand.

Even though the solar dryer is designed to dry algae in order to gain bio diesel out of the algae it can also be used for the whole energy production with the usage of microalgae as base. As a result of this we are able to reach a larger target market.

Another way of differentiating our product is the service we offer. It will include the installation of the system, dedicated customer care and after sale service. This service packet supports the approach creating long-term engagements.

3.7.2. Price

Price policy consists of the following tasks: corporate objectives, analysis of price situation, price level strategy, operative price strategy and price adjustment. Researching consumers’ behaviour and differentiating each aspect is important as it indicates how they will react on price fluctuation. We cannot define a price for our product yet, but we will set a price for the future product, because referring the price it is necessary to think about the adjusted product and not about the prototype designed for ISEP. To set a price in general every material and service have to be defined. For instance, we have to consider acquisition costs as well as profit margin. The price strategy plays an important role for a long-term successful development. Analyzing our product the price has to consider the following Material, building, distribution of the product, laboratory, cost of labor firstly.

All these components are not cost-intensive, so that a skimming strategy is not recommendable. Furthermore, we are not new in the market but with a quality product, which will fulfill specific needs. Anyway, the premium strategy is not countable for our product. There are more parts referring to the price clarified in the following.

Once our product is spread to Europe our approach is being in the lead of service. This service package will be sold as bundle to lower the cost for our customer. Additionally, through consisting opportunities, which are already mentioned in the section above, we will be able to produce the dryer at lower cost.

In terms of being a start up organization it is necessary to be profitable and gain as much market share as soon as possible. Achieving these goals, we are going to use the penetration strategy. Therefore we have to save costs and set a lower price in comparison to our competitors. In general, saving costs is realizable through an efficient purchase and with an increasing number of sales. In our case different options have to be considered because a certain number of reasonable sales figures cannot be forecasted.

Another opportunity is getting an agreement with a bank with the objective of a credit designed for start-up organization. We need to have low interest rate, as well as a long period of validity. Only then it would make sense to have an agreement in order to defray some of our costs. To arrange such an agreement a detailed business plan demonstrating that we have a product with good opportunities in the target market will be the a prerequisite.

Comprising our pricing strategy the price is defined in two ways. On one hand lowering the costs in order to quickly earn market share. On the other hand, the price includes the complete service package and every defined task which is listed above. Finally, we are going to use an appropriate penetration strategy.

3.7.3. Promotion

Even though that intensive and penetrating communication is cost-intensive it is very important to provide information to the customer purchasing our product. The costs associated with promotion constitute the various types of advertising the product. Promotion is communicating with the client and fulfilling their wishes. Finally, successful promotion influence sales numbers and thereby it also has an impact on the allocated costs.

The budget determines the usage of different opportunities in promotion. To gain our organizational approach we have to use direct as well as indirect promotion clarified in the following.

Direct promotion is usable to carefully listen to prospects’ needs and arouse attention to our product. In terms of our communication strategy, it will include several defined tasks starting with a trade show. The face-to-face contact with our prospects and customers is very important and is the prerequisite to establish a long-term relationship. Referring to our given budget a trade show is too expensive so we decided to share a stand with other universities or companies. On this stand we will provide our literature. Which is the right trade show? This is a really important decision in order to launch our product successfully. We always have to make sure that our prospects as well as the competition are aware of our product.

Examples for possible trade shows to take place are the following:

1. Algae Biomass Summit [23]

2. Algae Europe [24]

3. International Algae Congress [25]

Another opportunity in terms of direct promotion is to participate on events or larger presentation at universities dealing with the usage of the solar dryer. The face-to-face contact with our target market can be intensified and the interest in our product can be increased. Below the direct communication also indirect concepts should be established in our promotion. Referring to our organization we already have the knowledge that allows us to design a collaterals or a website. One team member studies industrial design and has the needed know how to concentrate on these topics. Concerning the budget it means that we can save costs and are able to spend money on other communication tools. For instance case studies in different economic publications are of interest. The budget does not allow us to place an advert but an option can be a short article in a dedicated magazine being read by our target market.

Finally, summarizing all tasks a slogan for our future development can be: “think global, act local”.

3.7.4. Place

An organization has to pay attention to distributing the product to the user at the right place at the right time. It is important to have an efficient and effective distribution in order to meet its overall perspective. In this case, two types of distribution methods are obtainable: indirect distribution through an intermediary or direct distribution without any middleman.

A variety of figures have to add value during the choice of the right distribution method. For instance it is easier to sell simple and standardized products by the usage of intermediaries then complex ones. Another factor you have to take in consideration is the financial background of an organization. A lot of finance is needed in order to distribute the product to Europe or even worldwide. These circumstances are different and finally, it depends on the product being distributed. Concerning our product three steps being taken in consideration.

In the first phase our product is going to be sold to universities. In the first two years we are focusing on Business-to-Business marketing. This allows us to have a better influence on different topics such as price, product presentation and service to satisfy our customer and get a closer customer loyalty.

To achieve the first contact we want to participate in larger presentation days and be present on several new technology meetings. It is our objective to hold our own presentation in order to present our prototype to a broader audience. The face-to-face contact allows us to answer to specific questions and to strengthen our network. As we want to establish a sustainable collaboration, our organization as well as our partner has to identify themselves with our product.

Phase two deals with the entrance in the European energy market. In this phase it is necessary to sell our product via Business-to-Business. The solar dryer is at this point still a specialized product and consequently it needs al lot of explanation. Through a direct connection to our final customer we are able to control the whole distribution and work on upcoming questions directly.

Through existing networks, which we have strengthen in phase one we can minimize costs and quickly pay attention to a larger target market. In general B-to-B marketing requires a lot of time and commitment to our product. In our case, we want to create long-term relationships. Therefore, we are going to sell our product without involving intermediaries via direct distribution. In parallel an on-going development in existing cooperation is placed in order to keep our product at the newest level.

Phase three refers to the remote future. Once our product is successfully launched in the European market (maturity stage) and we believe that there is also a demand for it in the American market as mentioned in the previous market analysis, our organization is already grown up, and has the required capacity to think global and act local. Following this strategy, we have to concentrate on local requirements. The American market mainly consists of companies with a large capacity and a focus on mass production, the same conditions as in the European market. Consequently, this market requires a comparable solution which is easy to establish and with flexible capacity. At this stage we can decrease costs by involving intermediaries in the American market for a successful communication and reach a larger distribution on the target market.

3.8. Budget

Our project’s marketing budget is about 5000€ for the first year. This budget forces us to be very careful and select those channels that we believe are the most suitable. Some of the activities listed below can be done by ourselves. We defined the following activities, which are covered by our budget:

• Website

• Collaterals

• Magazine (case study)

• Trade show

• Presentation at selling events

Website and Collaterals can be administered and designed from by one team member as mentioned above. The printing of about 1000 leaflets costs around 400 €, and the website domain has to be bought [26] [27]. With the usage of the case study mentioned in the promotion strategy we are able to save costs. Joining a trade show with an independent stand (acting as exhibitor) cannot be managed with our given budget. Therefore, it is our objective to join trade shows together with one or two partners. Also these costs are in progress as well as numbers for presentation at universities and selling events.

3.9. Controls

Monitoring the marketing plan is one of the most important tasks in order to be successful and to achieve results. No planning without control. Marketing control is the progress of monitoring the plans as they proceed and adjusting where necessary. In this case control parts need to be taken in consideration. Effective controlling consists of several tasks starting with the right characteristics of defined key performance indexes and is to be finished by taking corrective actions. The affected indexes should be flexible and adjusted to internal requirements such as management. In our case the actual performance of the solar dryer has to be controlled and compared to similar products in order to set standards. Referring to our project, we also have to pay attention to technical changes in order to early identify future trends. Benchmarking could be a good sufficient tool for this kind of analysis. As a result of this we, either are able to set standards or if needed take corrective actions. For instance, the customer care and even the after sales service should regularly clarify the prevailing situation. This could be done through surveys in an email or by our call centre. Controlling components concerning our project are the following:

• Sales analysis

• Market share analysis

• Quality control

• Customer Relationship Management (CRM) system

• Service levels

Resources to measure and monitor these approaches are scarce and costly. Consequently it is really important to work efficiently in order to set the right standards and take the right corrective actions.

3.10. Conclusion

Marketing is the process of identifying customer’s requirements in order to adjust and develop the organisations strategy successfully. Therefore we did a market analysis which shows that our main target market is placed in Europe and America. The demand for a solution such as the solar dryer exists. Comparable solutions is not available and most of the existing solutions are inflexible and without a variety of functions. A suitable segmentation as well as strategy are the reasonable basis to implement defined objectives. To enter the European market our product needs to be adjusted to future needs. To achieve this we are going to sell our product to universities first. Through an appropriate collaboration it is our aim to create a solar dryer which is adjusted to future requirements such as large function variety, easy to establish, meet the customer’s sustainable approach, runs only on solar energy, and has less energy consumption. With a continuous enhancement we believe that we can meet the long-term requirements of the energy market. In order to react on upcoming questions directly we want to sell our product in a direct distribution in this case via Business to Business. This way of distribution (direct) gives the opportunity to control the whole process including the face-to-face contact which is really important because our solar dryer is still a specialized product.

With the usage of an customer oriented service such as Customer Care and an on-going product development we will gain the needed know how as well as customer loyalty to launch our product. All in all we will develop a solar dryer with low energy consumption to replace current systems, adapted functions for specific requirements, and specialized service.

4. Sustainability & Eco-efficiency

4.1. Introduction

Nowadays, the matter of saving our planet is of great importance. People get more and more conscious of the possible dangers and threats towards environment. Due to that, all the producers and manufacturers of all the branches of industry think of ways to create new products in an ecologically friendly manner. Our project focuses on developing a new project, hence we want to create it and make it as environmentally harmless as possible. Due to that, we made a thorough research on already existing companies present at our field of interest. What we found out is that all of current algae drying companies creating different kinds of equipment like centrifuges, use and waste a lot of power in order to get the algae dry. The aim to be competitive on the market forces us to attain one of possible directions: either we mostly focus on drying algae faster or we make it as energy efficient as possible. We decided to follow the second idea. Thus, we create the algae dryer completely dependent on renewable source of energy – solar power. However, not only is our device energy – efficient, but also the greater idea behind it is very sustainable. An algae dryer serves for drying algae, which then can be used to create biodiesel, extremely advantageous as far as current excessive fuel consumption is concerned.

4.2. Biodiesel

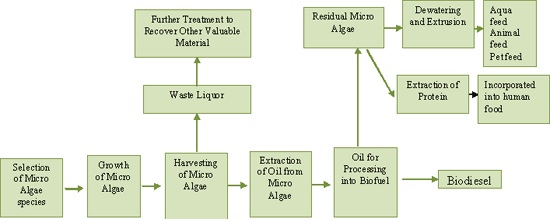

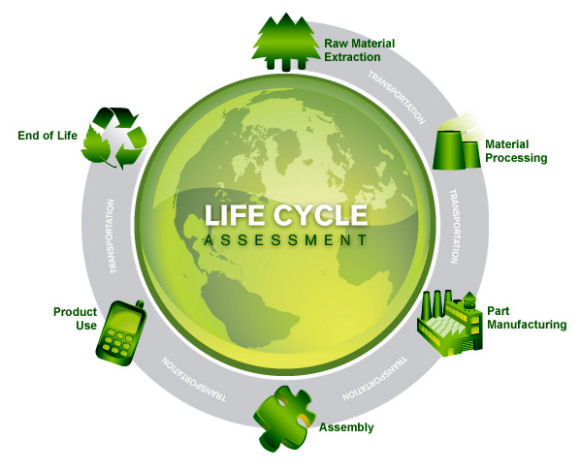

It is already widely known that the planet is running out of its fuel resources. Due to that people are searching for alternatives for oil and transportation fuels in general. One of such solutions is biodiesel obtained from microalgae oil. In order to extract such oil, microalgae must be first selected, grown up and harvested, which may be implemented in numerous ways. And here lays the importance of our project. One of the methods is drying algae in order to get rid of the unnecessary water. Then, the oil must be extracted, which again can be done in different manners. Later on, such bio-fuel would be transformed into biodiesel. The diagram in Figure 12 represents the simplified process of obtaining biodiesel from micro algae [28].

Figure 13. Process of biodiesel receiving [28]

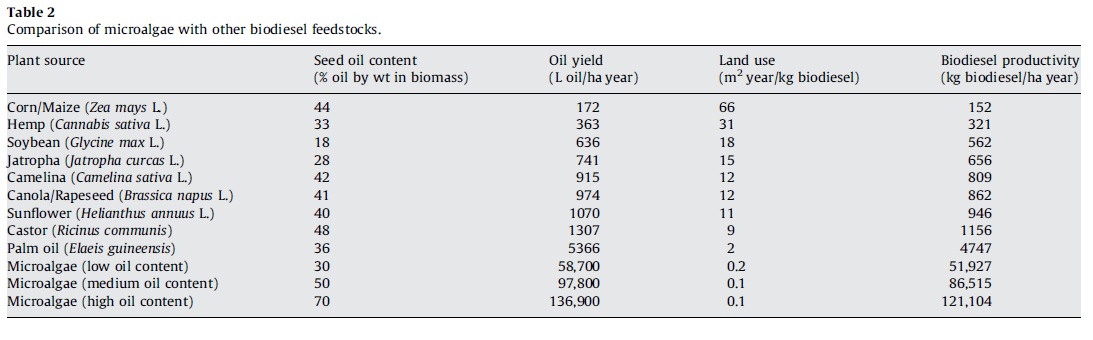

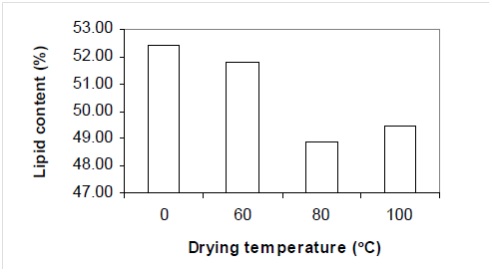

Observing the presented diagram, we may also notice that any side products or leftovers of the process can be reused or recovered. This proves the eco–friendliness of algae cultivation. There are also numerous other microalgae sustainable properties. For instance, they are able to grow almost everywhere. What is more, different specious can easily adapt to the diversity of environmental conditions. Thanks to that they are very competitive to other energy crops used to produce bio fuels (rapeseed, corn, soybeans). Their competitiveness justifies also the fact that one can return 10 to 100 more fuels and use from 49 up to 132 times less land area growing algae comparing to already mentioned crops. The table below (Table…) presents the lipid content and productivity of microalgae in comparison to other energy corps. It is clearly visible that microalgae have a great ascendance as far as oil content and biodiesel productivity are concerned, having the lowest area consumption at the same time.

Table 14. Comparison of microalgae to other biodiesel crops[29]

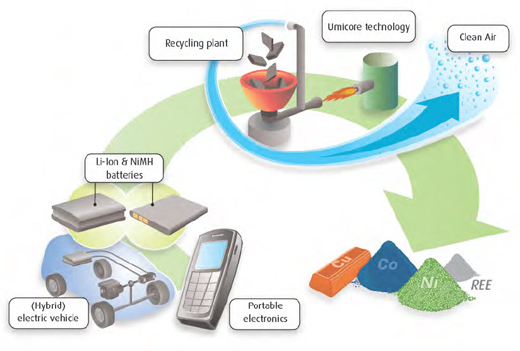

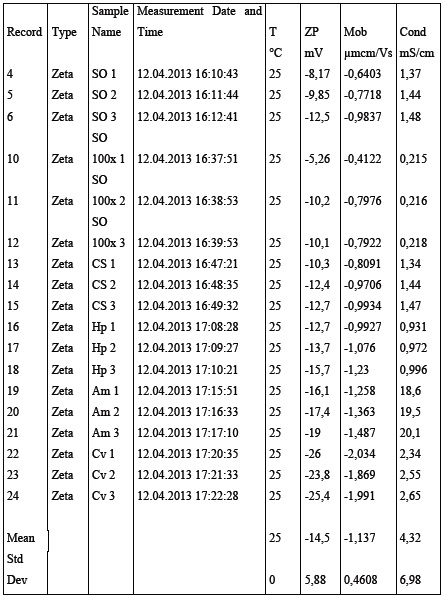

Moreover, algae are so called “bioremediation agents”. Meaning, they are able to absorb significant volume of CO2, which makes them very beneficial as far as fighting excessive emission of CO2 is concerned. In addition, they are also able to get rid of the dangerous nutrients and toxins from wastewater and sewage by growing in the polluted water and using the contaminants as nutrients. The simple scheme in Figure 13 demonstrates the microalgae cultivation cycle. As it can be observed, the continuous process is purely sustainable [28][29].

Figure 14. Biodiesel development cycle [28]

4.3. Sustainability

4.3.1. The importance of sustainability in our project

According to Oxford Dictionaries sustainability means “conserving an ecological balance by avoiding depletion of natural resources”[30]. Other sources, for instance, the World Commission on Environment and Development claims that sustainability is to meet the needs of the present without compromising the ability of future generations to meet their own needs[31]. Generally speaking, the common understanding of sustainable engineering and development, which cannot be rigid, is facing humans needs, yet not deteriorating the Earth at the same time. Essentially, our project serves this mission. Not only does it use a renewable source of energy to run the system and recyclable materials, but it also concerns the development of a system to harvest microalgae, which may be used to produce bio fuel.

4.3.2. Main aspects of sustainable production

Sustainability consists of three main pillars: environmental, social and economical one. In these broad fields one may point out several requirements that must be met so as to work for a real sustainable development. With the purpose of describing those areas in terms of our project, it is necessary to distinguish two possible ways of consideration. First, sustainability as far as the algae dryer prototype (main product of our project) is concerned. Then, its production on a larger scale. Taking into account the fact that the real sustainable conditions of such product are currently unavailable, our considerations are so far only probabilities and estimations.

We will start by approaching the environmental criteria of the sustainable development of the product we propose. In order to introduce it into the production of the design, it is advisable to follow and take advantage of several approaches and tools. Firstly, the concept that sustainable development has to be able to renew the resources at the same or greater rate than the pace at which they are consumed [32]. This concern brings our attention to the renewable sources of energy, which usage will be described later on in this section. Furthermore, life cycle analysis make it possible to obtain a good overview of the product impact on the environment. Such an assessment can also be found in the proceeding subchapters of this report. Another important issue is the fact that sustainable engineering ought to be competitive to the non-sustainable one. Meaning, the sustainable process outcome and the customer needs of the product must be met at the same satisfaction level as in the conventional approach to achieve success in the long run. The last, but equally important factor is eco–efficiency orientation. Aiming at production of goods in a sustainable manner, one needs to stick to eco–efficiency assumptions, which are described in the next part of this chapter.

Coming to economical issues, people not only need to be aware of the invested amount of money, but also of the operational costs of the device. In order to minimize expenses, we will use as many as possible accessories already available at ISEP. Most of the accessories needed are taken from the university. The running costs are also low. That is due to the fact that device is run on the solar energy, hence the solar algae dryer is completely autonomous as far as using other, to be paid, sources of energy are concerned. Taking mass production into consideration, it is equally important to buy necessary materials at local suppliers to limit time and transportation expenses. Thinking of our design even broader, we may be a contribution to investigation over alternative sources of fuel. Such market field is at its peak nowadays and may be very beneficial. If the product gets accepted by Universities, we may even consider sales network.

The last part is the social concerns, which involve not only growing issue of being ecologically friendly, but also getting involved in research over alternative sources of energy. The social factor also stands for securing the future. By being a part of such venture, we make ourselves and others willful of ecology protection and aware of potential threats to the future of our planet. What we are also doing is rising the current generations with the environment consciousness in their minds.

All of the presented sectors are interrelated and cannot be executed separately. It is important to take care of all the aspects in order to achieve good sustainability practice.

4.4. Eco – efficiency

The eco–efficiency is basically increasing the production of goods with reduction of resources, pollution and waste input. According to the World Business Council for Sustainable Development being eco-efficient is wise as far as business issues are concerned. One may conclude that attaining eco–efficient attitude is allegedly a tool companies could follow in order to run business strategies towards sustainability. In accordance to World Business Council for Sustainable Development [33], eco–efficiency can be considered in seven broad perspectives. We present a brief overview of our design with regard to those general objectives.

4.4.1. A reduction in the material intensity of goods or services

This first aspect include decreasing utilization of materials, water or land. As far as these criteria are concerned our aim is to recover the water from algae drying rather than using more of it. Taking into account materials and usage we would like to present two perspectives, first considering building the prototype, second regarding building our product on a larger scale[33].

4.4.1.1. Land

Let us first start with usage of land. The area occupied by the dryer prototype equals to around 0,5 m2. Such area is devoted to dry 5 l solution of microalgae. If we assume that replicated product would be able to dry 50l of solution, we may estimate that the total area needed for solar algae dryer would be equal to 5 m2. Those numbers on the other hand do not mean one needs to devote the land to install the device. Our aim is to make the design portable, so that no land needs to belong to the algae dryer both as for prototype and large scale product.

4.4.1.2. Materials

As far as prototype building is concerned, we tried to take advantage of as many parts available at our university as possible. These include the pallet as a support, some electronic parts, pipes or plastic containers. Considering large scale product, we foresee buying needed materials in large quantities and store it in the production magazines. We are designing a product, which does not involve any material production, but only assembling already existing parts. All the issues connected to the material disposal, so for instance recycling and utilization are presented in the following sections of this chapter.